Beyond the Electric Car

5 Innovations Making Vehicles More Sustainable

Say “sustainable car technology” and the conversation you’re having will likely leap to a Prius or Tesla and the magnificent miles they drive on relatively little or no gas. But there is a world of chemical advances out there that help make cars more sustainable, beyond engines that run on battery.

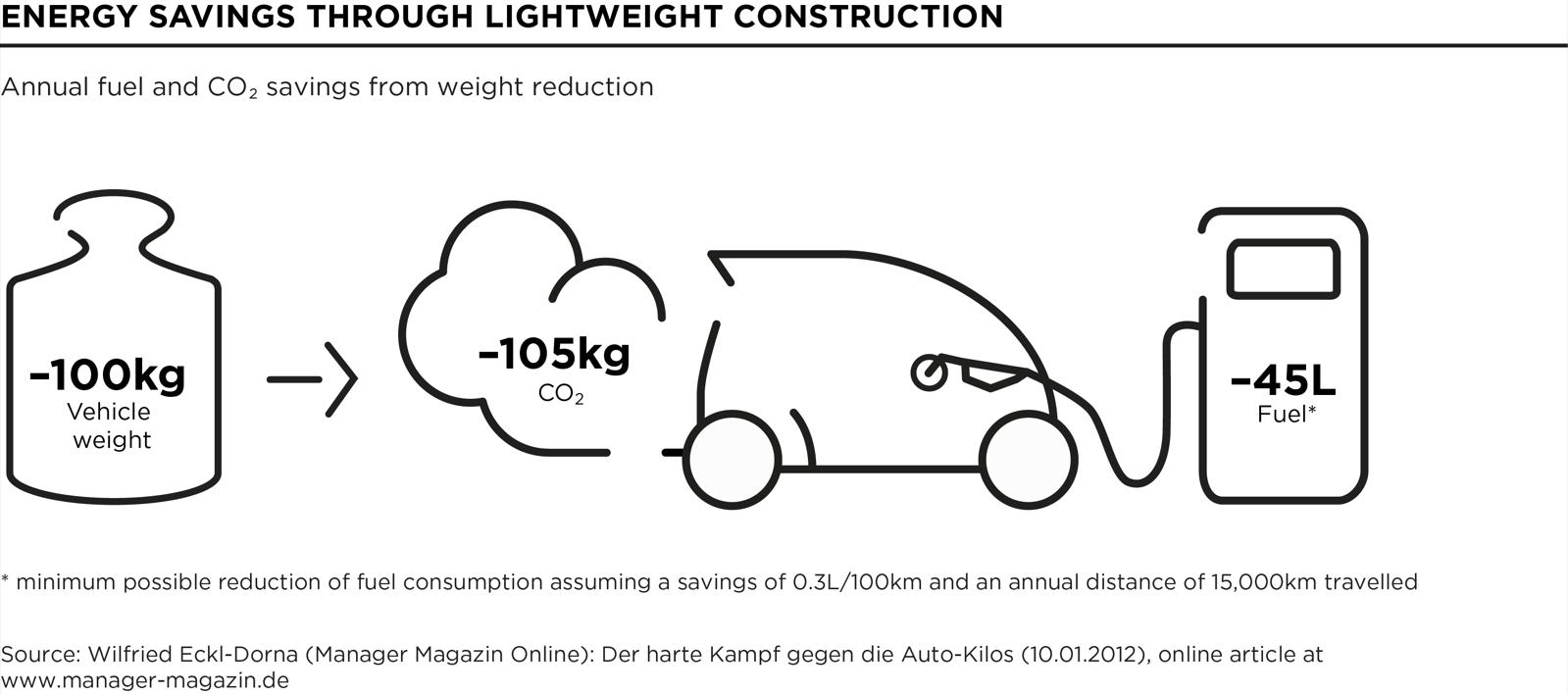

Many of these components work in reducing the vehicles’ weight, resulting in less drag and less gas needed to fuel them. McKinsey & Company projects that the lightweight materials in cars will rise from 30 percent today to 70 percent by 2030, as auto manufacturers try to cut more bulk and gain additional efficiency from alternative propulsion and fuel-saving systems. But beyond weight shedding, sustainable car technology is also about reducing harmful emissions and minimizing the chance of accidental fire through the use of blaze-retardant materials.

Below are the top five Clariant technologies that have helped make cars more sustainable, even before the advent of the electric engine:

1. Hydrocerol™

Hydrocerol is a full range of chemical foaming agents (CFA) used in the manufacture of foamed thermoplastics and can be applied in a vehicle’s interior parts, including door panels, ceiling panels, headliner trim pieces, instrument-panel components, as well as exterior parts. During the core back injection molding process, the CFA is activated by heat, reducing the density of the plastics component. Despite their lower weight, finished parts have excellent dimensional stability and maintain a high surface quality. Hydrocerol technology allows automotive brand owners and part producers to maintain both stringent physical specifications yet reduce overall weight, which in turn helps automakers meet emission standards.

2. Licocene™

Licocene is a ready-to-use adhesive polymerized by Clariant that allows for easier recycling of car carpets as well as flooring, and sun visors in the vehicle interior. About 4 billion pounds of carpets are discarded in the United States each year, research shows, and recycling them is very energy- and labor-intensive work because their materials need to be separated. Licocene, however, eliminates the separation step in recycling because it's polymer based– the same material car carpets are made from. It combines the best features of a polymer, with flexibility and high mechanical strength at low molecular weights. The low melting points and viscosities of the adhesive make optimum processing possible at low temperatures. And due to its low density compared to latex, for example, the weight of products made from Licocene, such as car rugs, can also be reduced.

Licocene was recognized for contributing to improving sustainability in the textile, plastics and coatings industries and was a finalist in the prestigious German business innovation award, "Innovationspreis der Deutschen Wirtschaft 2015.”

3. Sunliquid™

In a fleet test with Mercedes-Benz vehicles over a period of 12 months, sustainable cellulosic ethanol, an advanced biofuel from Clariant’s Sunliquid™ process, was used as Sunliquid™20 (a fuel containing 20% cellulosic ethanol by volume, E20). This highly sustainable fuel, manufactured by Haltermann Carless, provided very good combustion properties with a high degree of efficiency and an attractive consumption profile compared to today’s standard E10 fuel. Clariant uses agricultural residues such as cereal straw and corn stover – leftover stalks, leaves and husks – to turn them into cellulosic ethanol instead of having to use biomass grown specially for the purpose. This allows greenhouse gas emission savings of up to 95 percent across the entire value chain, without the need to compete with food production or tie up agricultural land.

4. Zeolites

As the emission standards in industrialized countries become increasingly stringent, catalytic converters in vehicles play a vital role in reducing emissions pollution. Clariant’s synthetic zeolites are an important component of the latest generation of diesel catalytic converter technologies: oxidation catalysts (DOCs), NOx storage catalysts, and selective catalytic reduction (SCR), which help convert harmful emissions into less harmful ingredients. Known as “molecular sieves,” zeolites are a diverse group of naturally-occurring minerals that mainly consist of aluminum oxide and silicon oxide. For decades, this porous filter mineral has been used in a wide range of applications from eliminating odors in cat litter to cleaning up toxic substances in soil. Synthetic zeolites can be designed for specific applications, such as to convert exhaust gases in diesel engines to less harmful ingredients such as nitrogen and water. Due to its highly porous structure with defined hollow sizes, Clariant’s zeolites are specially optimized to be used as an ideal carrier material for the catalytically active metals necessary for neutralizing pollutant gases. Additionally, zeolites behave as a trap for dangerous hydrocarbons during the engine’s cold start phase, preventing pollutants from being released before the exhaust gas reaches necessary temperatures for catalytic reactions to occur.

5. Exolit™ OP

Nearly 2 million vehicle fires were reported on U.S. highways in the decade to 2016, an average of 555 a day, according to records kept by the National Fire Protection Association. Short circuits, for instance, can easily lead to ignition. By using Clariant’s Exolit OP products in potential ignition sources, like electronic components, this risk can be reduced considerably. In the event of a blaze, flame retardants can slow down the fire and increases the chances for people to survive a vehicle fire unharmed. Also fewer emissions of volatile organic compounds and other dangerous gases occur with Exolit OP compared to traditional halogenated flame retardants.