Styrene catalyst portfolio

Styrene monomer is an essential base chemical for the polymer industry. It is most commonly produced via catalytic dehydrogenation of ethyl benzene (EB).

The EB feed is mixed with superheated steam, and the gas is passed over the catalyst bed in a two- or three-reactor configuration. The process consumes vast amounts of heat, and must be operated under reduced partial pressures.

The key to economically and environmentally sustainable styrene production is the ethylbenzene (EB) dehydrogenation catalyst. Clariant’s StyroMax™ catalyst series provides best-in-class performance, and suits all EB dehydrogenation technologies.

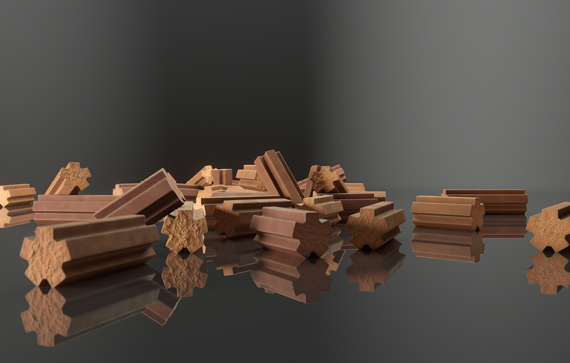

For plants experiencing reactor pressure drop, we also offer StyroMax rib-shaped catalysts, with a unique design to drastically reduce pressure drop by 30% to 50%. Learn more about our unique technology.

Adding customer value

ROBUST CATALYSTS

> 1000

production cyclesusing Clariant styrene catalyst

EXPERT SUPPORT

11

regional engineering officeslocated close to our customers

EXTENSIVE EXPERIENCE

70+

years of improving styrene yields

and lowering steam consumption

Choose your StyroMax

STYROMAX UL-100

This innovative catalyst achieves exceptional performance at unprecedented low steam-to-oil ratios (S/O) of 0.76 by weight, setting a new industry benchmark in SM production efficiency.

The StyroMax UL-100 has been specifically engineered to facilitate ultra-low steam-to-oil operations in styrene plants for drop-in refills into existing units, through revamp and for grass roots projects.

Through an alliance with Technip Energies, this cutting-edge catalyst technology will enable plant operators to significantly reduce steam consumption while maintaining optimal production rates.

Tune in our latest podcast with Hydrocarbon Processing

STYROMAX UL3

StyroMax UL3 is the first ethylbenzene dehydrogenation catalyst to offer ultra-high selectivity and ultra-low steam-to-oil (S/O) ratios. This makes it the most cost-efficient styrene catalyst globally.

It is also highly resistant to coke formation, and proven to promote reliable styrene production with the lowest steam consumption.

STYROMAX 9

StyroMax 9 is the latest generation of our styrene catalysts, leading the global market for units with steam-to-oil (S/O) ratios above 1.3.

Compared to previous catalysts, it offers much higher activity, and far greater resistance to deactivation. Producers benefit from lower steam costs, higher yields, and longer production cycles.