Customized chemical technologies for the end-to-end mining process

Clariant Mining Solutions is a trusted global provider of specialty chemicals for mineral processing, with a focus on creating value by improving metallurgical performance for our customers. We offer customized solutions for the end-to-end mining process, including innovative technology in froth flotation chemistry and emulsifiers for explosives.

Our global network of local application and development centers coupled with our rapid response to customer requirements, allow us to deliver high performing products and unmatched services. We formulate tailor-made chemical solutions specific to your mine, with high respect for the environment through sustainable chemistries. Click to read more what sustainability means to Clariant.

Our experts concentrate on specific ore applications, such as copper, zinc, nickel, gold, and other sulfide ores, iron ore, phosphate, potash, lithium, and many other industrial minerals, as well emulsifiers for explosives, serving mining operators world-wide.

Clariant Mining Solutions - World leaders in innovation

Sulfide Ores

Optimize your recovery and improve grade with specialized collectors and frothers

Iron Ores

Complete beneficiation solutions with flotation reagents, agglomeration additives and filter aids

Industrial Minerals

Customized flotation reagents and fertilizer additives to optimize your operations

Emulsifiers for Explosives

Emulsifiers for bulk emulsions, packaged explosives and specialized applications

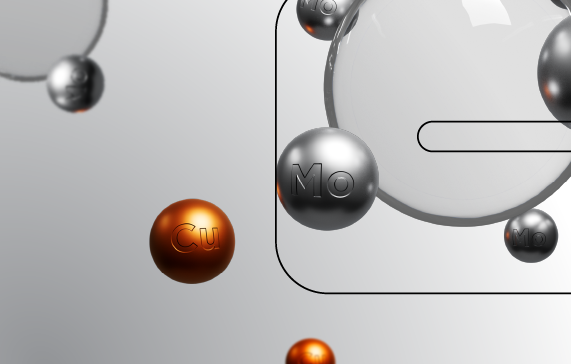

Clariant now has a safer technology for NaSH replacement in molybdenum flotation: FLOTICOR™ DP SULFIDE DEPRESSANTS

They are proven in commercial production of molybdenum concentrate with excellent results, and unlike other alternatives, they enable complete replacement of NaSH in the separation of copper and molybdenum. Let´s work together to see what FLOTICOR™ DP sulfide depressants for NaSH replacement can do in your operation!

Clariant Mining Solutions Innovation - safer, sustainable sulfide ore reagents: XANTHATE replacement technology

Clariant’s customers were concerned with the safe handling and performance of xanthates in their operations. Through collaboration, we developed sustainable alternatives with high copper flotation performance and safer handling and disposal for mines, lowering capital expenditure and providing a longer shelf life than solid xanthates.

Working with the mining industry to build a more sustainable future: DECARBONIZATION MINERALS PROGRAM

The decarbonization of the production of goods and services as well as the transportation of materials and people is a growing megatrend as corporations and individuals seek to lower their enviromental impact. Through our Decarbonization Minerals Program and global Competence Center for Decarbonization Minerals, we are dedicating resources to developing new flotation reagents and other processing chemicals so that mining companies can optimize their benefication plants.

Working together to build the future of mining: TAILINGS MANAGEMENT PROGRAM

Are you also thinking about a different future for mining? Of greater efficiency, or new ways to deal with tailings? Clariant’s Tailings Management Program and global Competence Center for Tailings Treatment in Belo Horizonte, Brazil, are dedicated to supporting sustainable mining and developing chemical solutions that will transform the way the industry deals with tailings. Bring us your challenge and our researchers will work to find the best way to solve it.

Read our articles

There are no articles related to this context.